Cooking

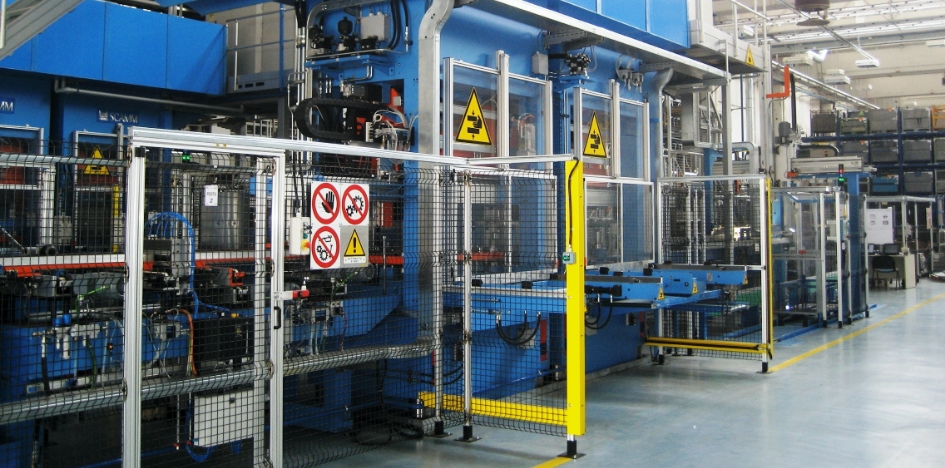

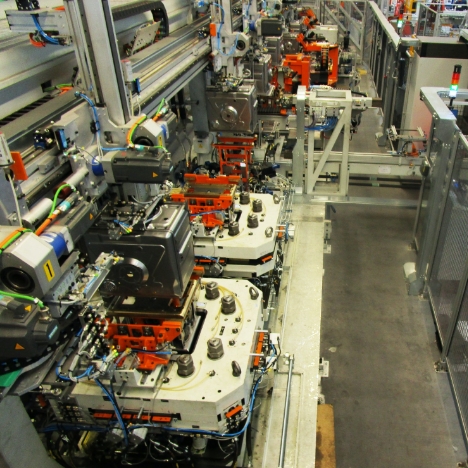

Our integrated systems

Automatic lines and equipment for the cooking sector include complete systems to produce:

oven cavities

side panels, outer shells, and oven components

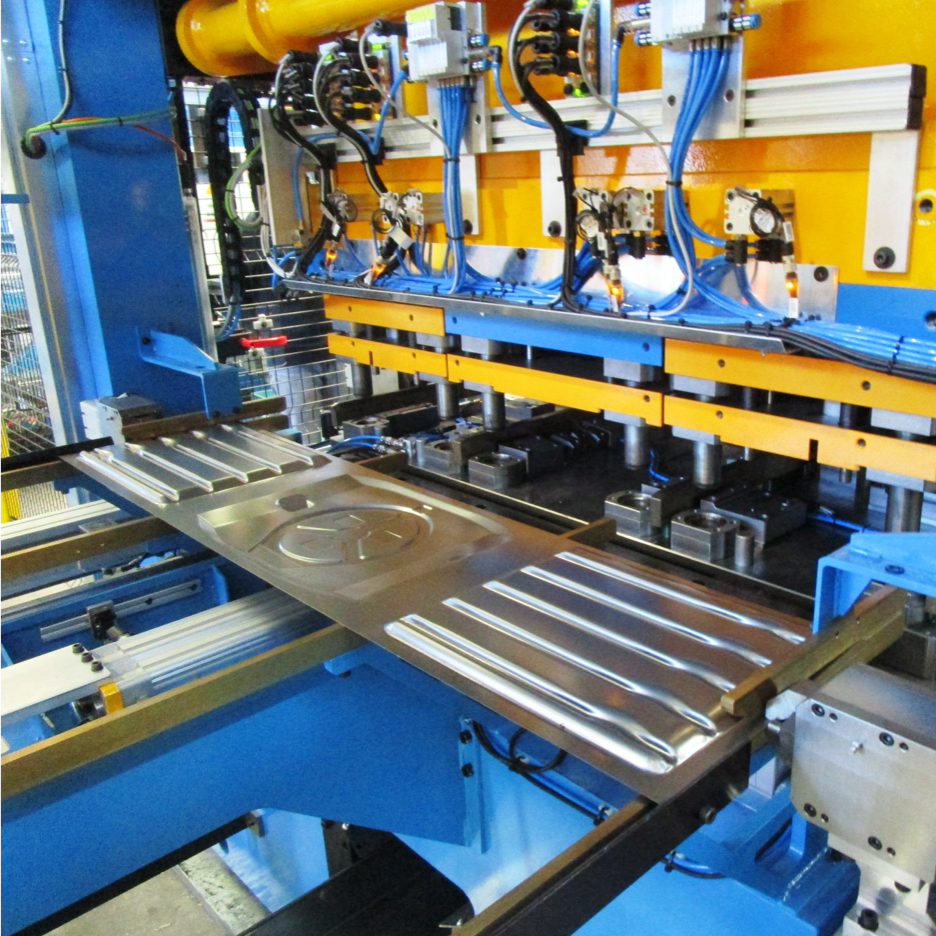

cooktops

hoods

SCAMM systems produce oven cavities which are the market's state-of-the-art and derive from the technological innovation driven by customer needs. A continuous production process improvement includes the initial cavity front flanging systems for thermal door separation, welding medium frequency parts and subsequent lamination, aesthetic assembly using coupling profiles ("Z" profiles), in-line customisation systems with continuous production versioning, and the most recent solutions for the continuous welding of multifunctional oven front frames (SCAMM proprietary technologies) and laser welding assembly.

Our solutions for oven cavities can be adapted by:

- product type (electric, gas, steam, multifunction, and microwave ovens)

- assembly technology (resistance, laser, and plasma welding)

- production material (enamelling steel, stainless steel)

- cavity structure (C-shaped, U-shaped, and O-shaped wrapper)

- level of equipment integration (stamping or part customisation press lines, dies, assembly lines)

Each automated system and equipment is a unique “ad hoc” solution developed alongside the customer and optimised to meet technical product requirements, production flexibility and productivity.

The production process quality is monitored by in-line integration with automatic control systems for individual processing operations, vision systems and dimensional controls.

Our products