SCAMM supports customers step-by-step to find a solution to every problem. Our company can offer turn-key solutions by acting as a unique reference from product and cost specifications definition through complete product design, manufacturing, and installation of equipment and production facilities.

The SCAMM approach helps streamline product design and testing while developing everything to the highest possible standards.

The SCAMM approach helps streamline product design and testing while developing everything to the highest possible standards.

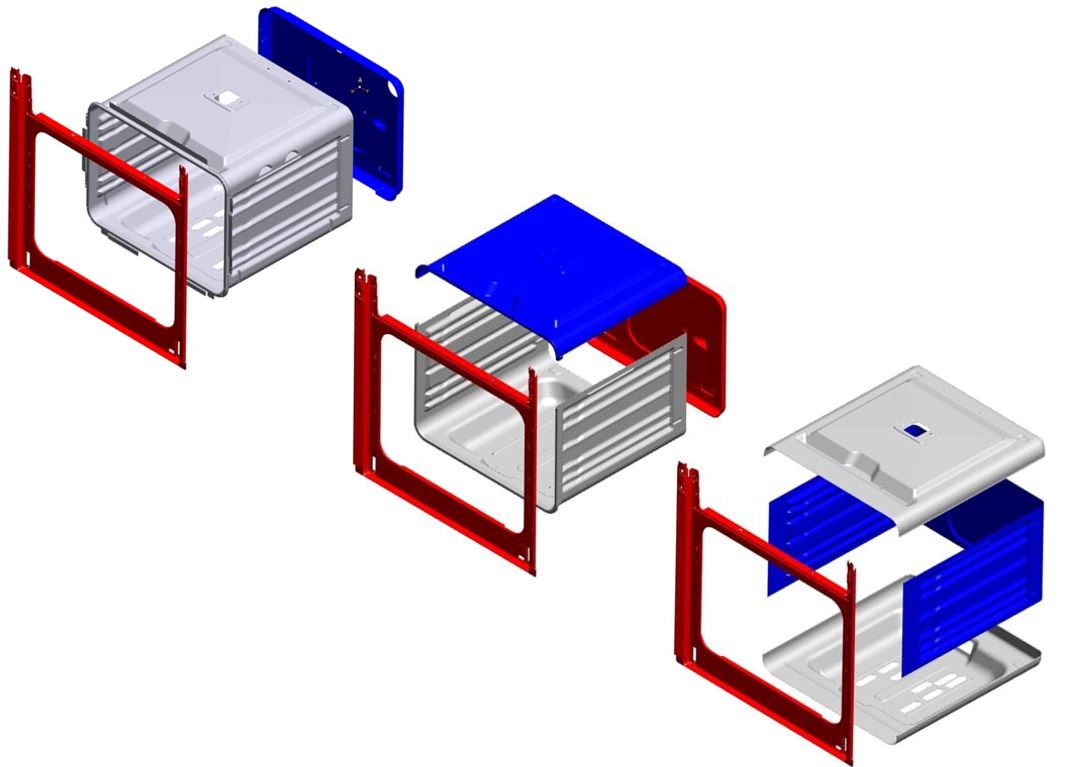

Product co-design

Product co-design with the customer is a critical phase in the success of any new project. The involvement from the first drafts of the design of our technicians specialised in the forming and assembly of structural sheet metal parts with the product designers is fundamental to design a product optimised in costs, reliability and production efficiency. SCAMM engineers can suggest alternative manufacturing techniques to improve build quality, save time, and reduce parts’ production costs.

It is the combination of product functionality experts with process experts that results in innovative and competitive products.

Our dedicated co-design team can provide innovative solutions for component manufacture and coupling. We can give immediate instructions on the best solutions and test and create prototypes in our laboratories during the preliminary phase to analyse new ideas and suggestions. In addition, we use CAE programs to verify the product feasibility and evaluate the best design features based on performance and process simplicity.

By cooperating with qualified partners, we can provide complete design solutions for household appliances. We define product range specifications, targets and forecast product costs and equipment requirements. Then, we design the product integrating mechanical, electrical, hydraulic, packaging and trade components, CAE analysis of resistance and performance (mechanical, thermal, fluid-dynamic, acoustic, vibrational, shock/impact structural simulations), laboratory testing of prototypes and validation.

It is the combination of product functionality experts with process experts that results in innovative and competitive products.

Our dedicated co-design team can provide innovative solutions for component manufacture and coupling. We can give immediate instructions on the best solutions and test and create prototypes in our laboratories during the preliminary phase to analyse new ideas and suggestions. In addition, we use CAE programs to verify the product feasibility and evaluate the best design features based on performance and process simplicity.

By cooperating with qualified partners, we can provide complete design solutions for household appliances. We define product range specifications, targets and forecast product costs and equipment requirements. Then, we design the product integrating mechanical, electrical, hydraulic, packaging and trade components, CAE analysis of resistance and performance (mechanical, thermal, fluid-dynamic, acoustic, vibrational, shock/impact structural simulations), laboratory testing of prototypes and validation.

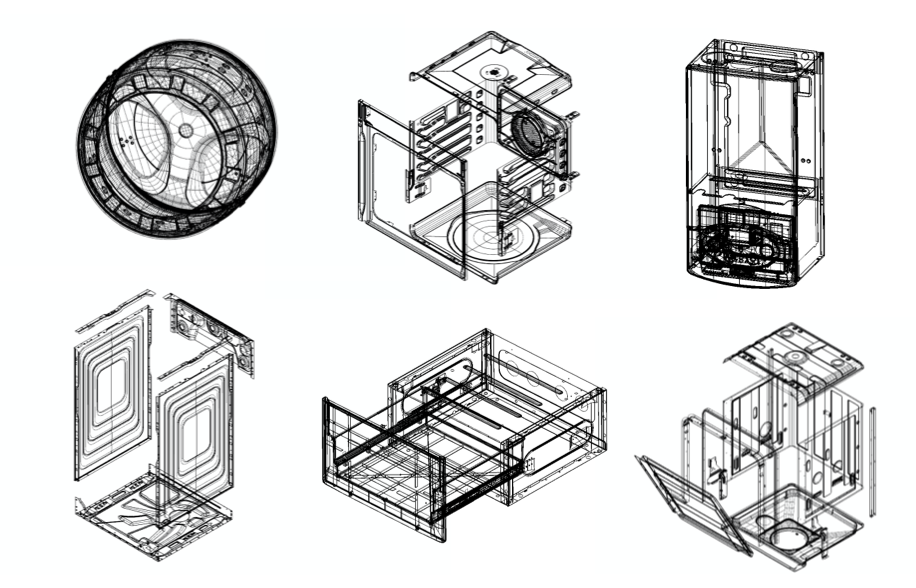

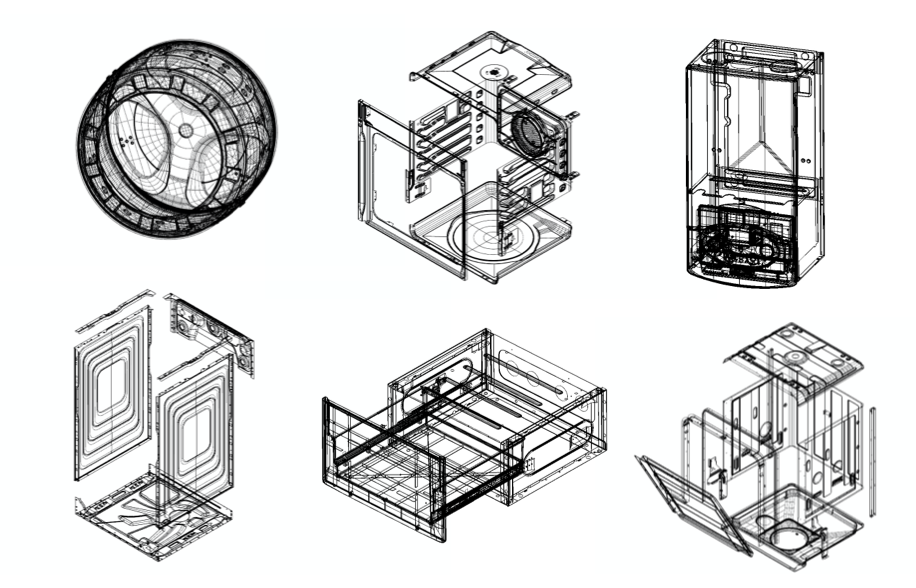

Prototype and pre-series

production

By making prototypes and pre-series, SCAMM can test a product concept, eliminate unwanted defects in the initial phase and create a functioning model.

SCAMM technicians can make simplified functional prototypes with the final project for the first assembly and functionality tests according to the needs. These are created using the equipment to create shapes, laser cutting and assemblies that reproduce the final product's technical features.

SCAMM makes equipment and soft-tool dies intended exclusively to produce an easily modified prototype. In this way, we can create different prototype campaigns following the product's technical evolution. Dedicated soft-tooling can more closely replicate the final product behaviour and produce additional prototypes more accurately.

Finally, SCAMM produces prototype series anticipating the die construction and essential machines and completing the samples with generic devices for projects with limited time to market but with the need to have models that faithfully replicate the product's critical features.

SCAMM technicians can make simplified functional prototypes with the final project for the first assembly and functionality tests according to the needs. These are created using the equipment to create shapes, laser cutting and assemblies that reproduce the final product's technical features.

SCAMM makes equipment and soft-tool dies intended exclusively to produce an easily modified prototype. In this way, we can create different prototype campaigns following the product's technical evolution. Dedicated soft-tooling can more closely replicate the final product behaviour and produce additional prototypes more accurately.

Finally, SCAMM produces prototype series anticipating the die construction and essential machines and completing the samples with generic devices for projects with limited time to market but with the need to have models that faithfully replicate the product's critical features.

Equipment modification,

retrofit and revamping

SCAMM puts its technical experience in the retrofit and revamping of existing equipment at the service of its customers by working at different levels:

- equipment upgrade, insertion of new models and new operations or reduction of cycle times

- equipment modernisation and line re-engineering with new technologies and the latest electronic and mechanical solutions to improve efficiency and quality

- restoration of the original functionality of the SCAMM-designed equipment replacing parts of the line at the end of its life, upgrading equipment to their original performance

In this way, SCAMM can extend and improve equipment productivity and final product quality.