Technologies

Technologies

Tecnologie

At SCAMM, we have always considered it central to keep critical processes in-house to ensure maximum control of high knowledge parts of our systems and in-depth expertise of all applied technologies, guaranteeing effective and rapid responses.

Our research and development team works to develop and improve SCAMM's technological range constantly. Commitment to research and development is crucial to what we do, as we seek to integrate the most suitable technologies to improve customer operations. With our in-house expertise, we can develop innovative technology for customer forming and assembly needs. At the same time, we continuously research and test the latest market technological innovations to integrate state-of-the-art systems and components into our automated systems that complement our in-house developed solutions.

Our research and development team works to develop and improve SCAMM's technological range constantly. Commitment to research and development is crucial to what we do, as we seek to integrate the most suitable technologies to improve customer operations. With our in-house expertise, we can develop innovative technology for customer forming and assembly needs. At the same time, we continuously research and test the latest market technological innovations to integrate state-of-the-art systems and components into our automated systems that complement our in-house developed solutions.

Automation

We are experts in mechatronics, which we apply to our equipment to automate production systems in different forms:

Robotic systems

Servomechanisms

Hydraulic/pneumatic systems

Transfer systems

Electro-hydraulic systems

Automatic vision and inspection systems

Assembly

Rotary roll seaming

Special machines for seaming parts on radii include dishwasher tubs (SCAMM technology), horizontal axis washing machine/dryer drums, vertical axis washing machine baskets (SCAMM proprietary technology for seaming plastic rings and bottoms).

Longitudinal seaming

High-strength rectilinear seaming for washing machine drums, up-and-over garage doors, busbar trunking systems and radial fan impellers.

Resistance welding

We carry out medium-frequency aesthetic roller welding for oven cavities, washing machine drums, water heater outer casings, tanks and combustion chambers, spot/projection welding for assembling washing machine cabinets, industrial cabinets, and drawers.

Laser welding

Aesthetic welding for washing machine drums, dryer drums, oven cavities, and dishwasher tubs.

Clinching

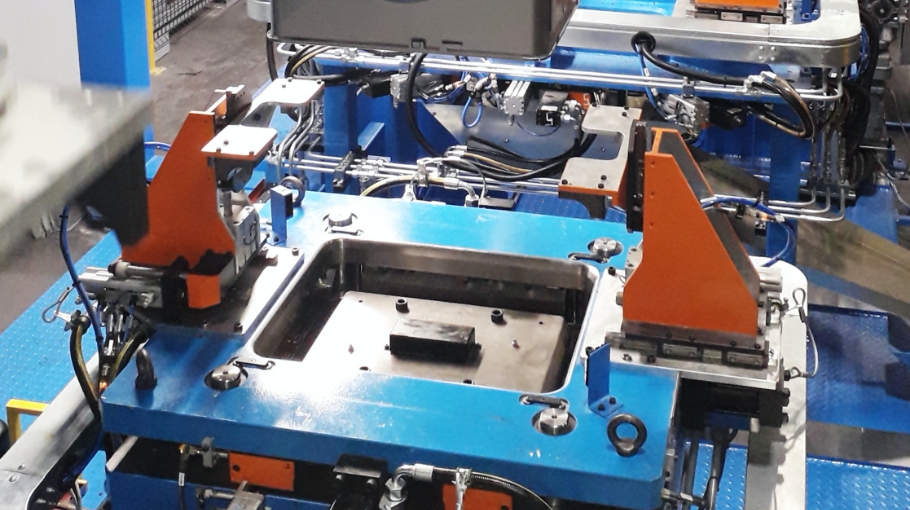

Machines for assembling sheet metal components such as washing machine cabinets, dishwasher tub components, top loading washing machine drum door components, up-and-over garage door panels.

Screwing and riveting

In-line systems and stand-alone stations for automatic fastening of sheet metal parts by screwing and riveting.

Forming

Diameter expansion

Systems for expanding the diameter of welded/seamed shells of washing machine and dryer drums.

Diameter reduction

Special systems for front and rear diameter reduction of welded/seamed dryer drums (SCAMM proprietary technology).

Expansion forming

Expansion forming on welded wrappers, Z-forming for top/bottom of oven cavities and for the oven cavities front opening (SCAMM proprietary technology).

Forming patterns and embosses

Embossing on welded/seamed shells, patterns on expanded drums, shapes on dishwasher tubs and oven cavities.

Groove forming

Groove forming on welded/seamed shells such as for vertical axis washing machine baskets, dryer drums, water heater tanks and combustion chambers.

Roll Bending

Two roll plate bending of thick wrappers such as for water heater tanks.

Rolling-up

Systems for wrapping shells and for coupling edges to produce laser-welded cylindrical bodies, such as washing machine drums, dryer drums, and water heater outer casings.

Roll forming

Roll forming to produce continuous profiles such as industrial and light shelving elements, gasket retainer for dishwasher tubs and metal door elements.

Bending

Servo-electric bending systems with interpolated axis movements to produce panels such as refrigerator doors and cabinets, dishwasher doors, side panels and cooker side panels. Servo driven folding machines for bending dishwasher and oven cavity wrappers, washing machine refrigerator/freezer cabinets.

Flanging

Front flanging of oven cavities, flanging of washer/dryer drum shells, and making flanges on sheet metal components and assembled products.

Piercing

Hydraulically or mechanically operated punching systems for in-line production of washing machine drum shells (pre-expansion or post-expansion), up-and-over garage door ventilation holes, special punching units for product customisation.

Stamping

We use all the technologies of sheet metalforming in designing our dies and special equipment:

- Deep drawing and embossing

- Shearing, punching, trimming

- Bending, flanging, curling

- Coining and calibration