Storage System

& Metal Doors

Storage System

& Metal Doors

Our integrated systems

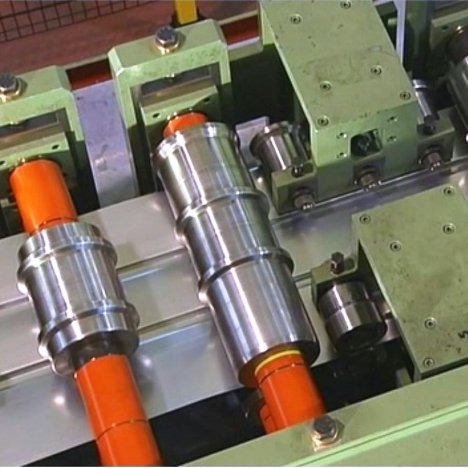

Decades of experience in sheet metal forming and the ability to devise flexible technologies for automating the production process have enabled SCAMM to work alongside companies in sectors where high productivity combined with high variability in the size and model range are required.

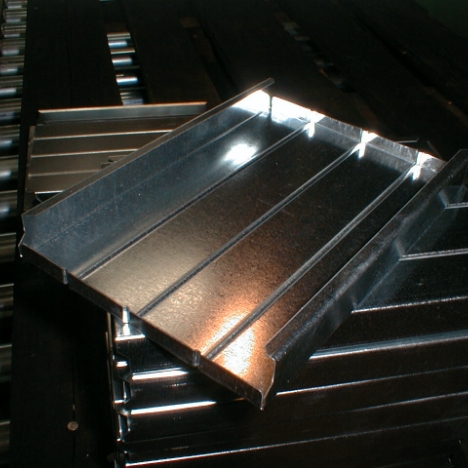

For the storage systems sector, SCAMM builds automatic lines to produce all the sheet metal components of any type of industrial shelving (shelves, pallet racks, cantilever, drive-in, coil racks) and light shelving:

- SHELFS production lines

- BEAMS production line

- CROSSBARS production lines

- STRUTS production lines

SCAMM can manufacture automated systems to produce metal cabinets and drawer cabinets, electrical cabinets, rack cabinets with:

- simultaneous processing of different sheet metal thicknesses

- high production flexibility for models and product sizes to be manufactured

- automatic model changes and set-up without production interruptions

- customised automation, layout and technical solutions

SCAMM can supply fully automatic production lines or semi-automatic machines to produce any door (standard, fire damper, garage) for the metal door sector. For galvanised steel up-and-over garage doors, we specialise in innovative solutions with the following features:

- integrated systems for the in-line production and assembly of all door components such as panel, frame, omega crossbars

- invisible panel joints by seaming inside the grooves (SCAMM technology)

- screwed frame and omega crossbars welded or clinched (for up-and-over doors without welding)

- panel and frame automatically assembled by spot welding or clinching (for seamless up-and-over doors)

- high production flexibility capable of producing the entire dimensional range of doors without interruption (10 mm width variability) and with different sheet thicknesses

- automatic in-line production of any model of door panel with automatic set-up and without interruption (fretted, micro-perforated, different ventilation cuts, lock/handle cuts, fanlights, horizontal slats)

- customised software system which sorts the production sequence to minimise sheet metal scrap and optimise the production schedule by considering various parameters (paint colour, place and date of delivery, sheet metal thickness, door model)

Our products